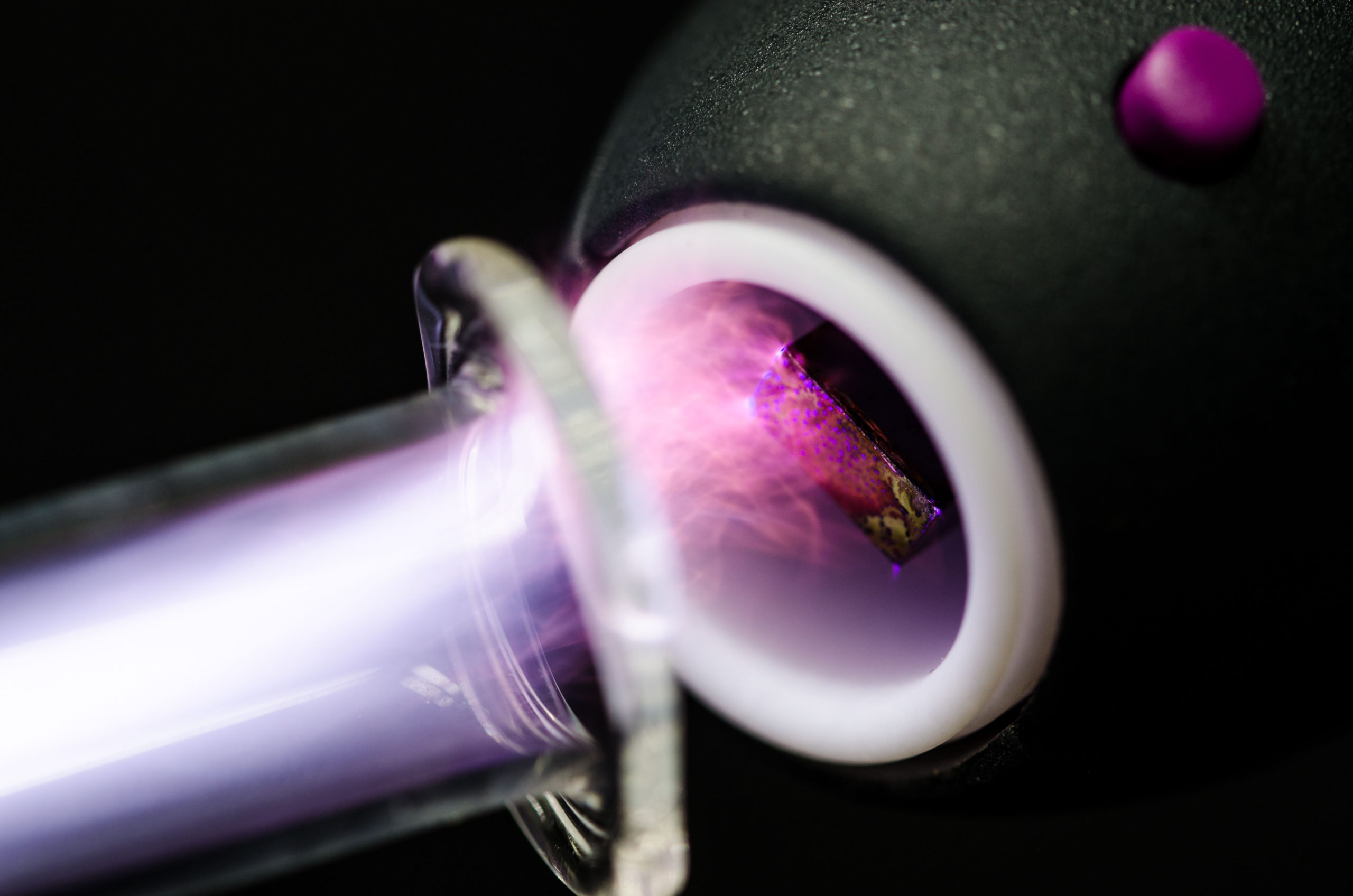

An ally that can create added value

When interviewed by Plastiques & Caoutchoucs magazine, Nathalie Seninck, CEO of STTS, underlined the fact that surface treatment innovations open up numerous opportunities regarding the choice of new shapes or new materials which have not yet been used. “Today, technologies can address 95-98% of adhesion issues, regardless of the material or the profile of the part. Some people believe that surface treatment is still very complicated, but in fact it’s a solution that can be totally integrated into the production process, thereby opening up new prospects and creating added value!”, she confirms.