To stand out from their competitors, plastic parts manufacturers are taking a growing interest in the finishing and decoration stages. As such, they can generate added value, both aesthetically and functionally. Manufacturers have the choice to integrate surface treatment procedures into their production process or to outsource them.

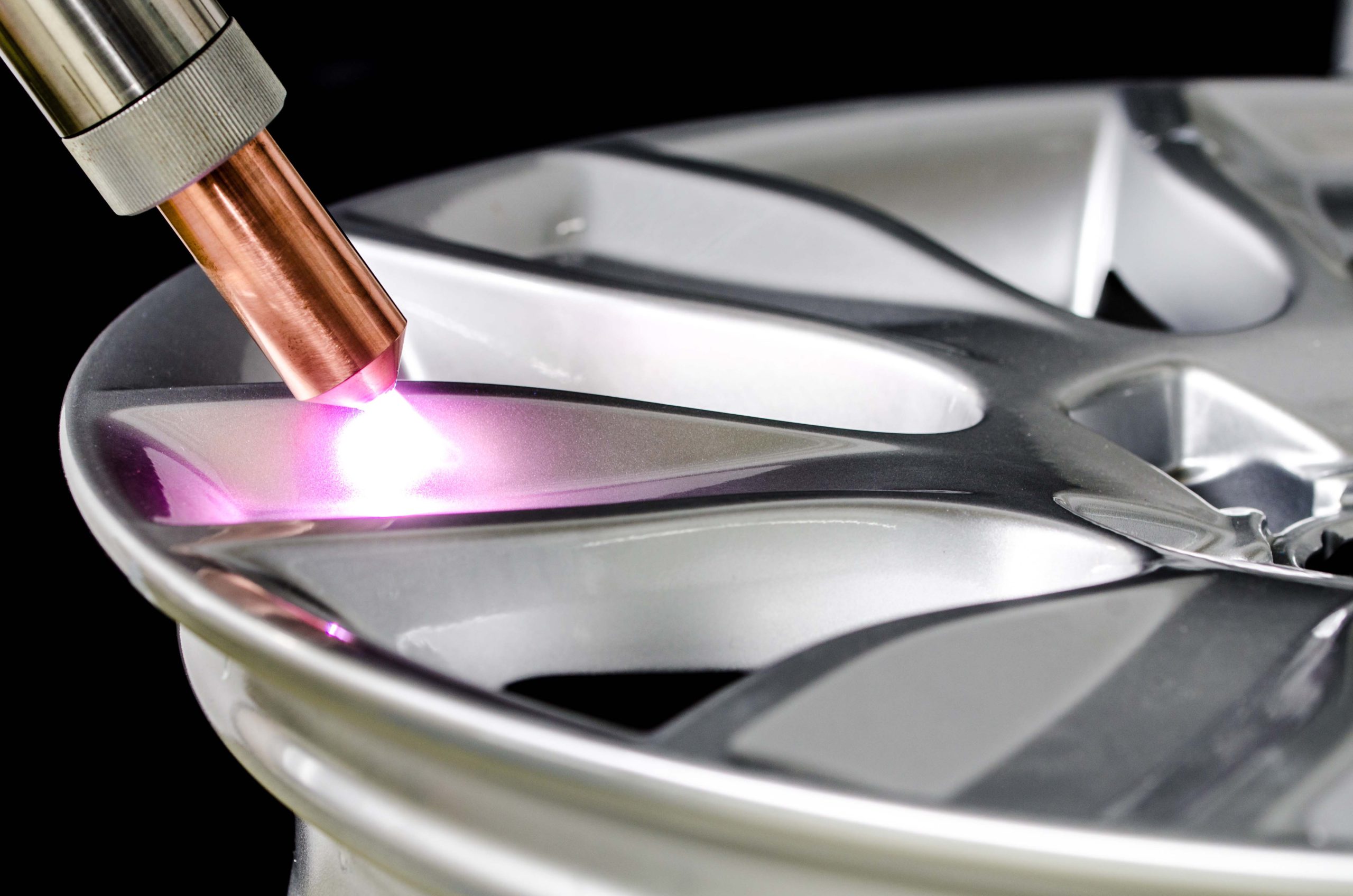

To make their decision, several criteria need to be taken into account, such as the volumes of a production run, its recurrence and the speeds required. “At STTS, our integrations tend to involve large-scale production lines or workshops belonging to decoration specialists”, explains Nathalie Seninck, CEO of STTS. “For small production runs, for example, the customer tends to place more emphasis on a flexible production line in order to handle several runs to fulfil various requirements. In this case, we generally guide them towards Corona discharge or cold plasma treatment systems. With Corona technology, for example, we offer several alternatives in terms of treatment stations.”